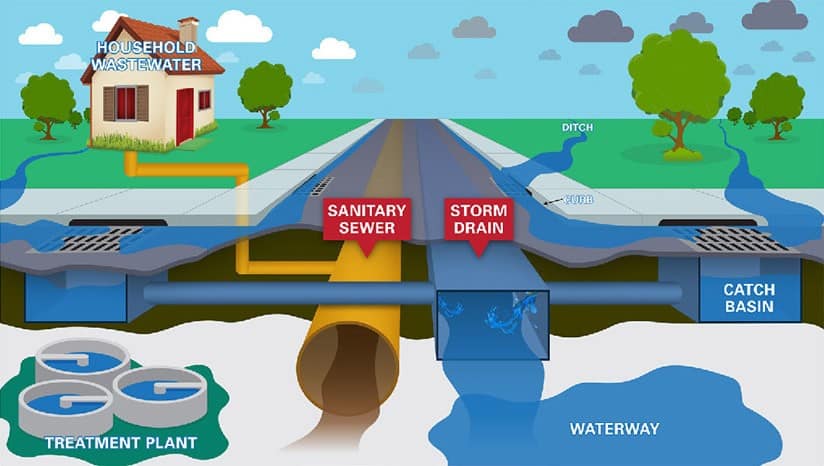

Drain systems are integral to managing stormwater and wastewater in residential, commercial, and industrial settings. These systems are built to withstand various loads and pressures, but understanding their load capacity is essential for ensuring their proper design, performance, and longevity. In this comprehensive guide, we will explore the concept of load capacity in drain systems, the factors that influence it, and how to design and maintain a system that can handle the necessary loads effectively.

Defining Load Capacity in Drain Systems

Load capacity, in the context of drain systems, refers to the ability of the system to withstand and manage various loads or forces that it may be subjected to. These loads can be categorized into several key types:

1. Hydraulic Load: This is the force exerted by the flow of water within the drain system. It encompasses both the regular flow of stormwater and wastewater and peak flow during heavy rainfall or storm events.

2. Static Load: Static loads are constant forces applied to the system, such as the weight of soil, pavement, or buildings above the drain pipes. These loads can exert continuous pressure on the system.

3. Dynamic Load: Dynamic loads result from temporary forces like vehicular traffic or heavy machinery passing over the drain system. These loads are characterized by their fluctuating nature.

4. Impact Load: Impact loads occur when objects are dropped or fall onto the drain system. These sudden forces can cause damage or displacement of components.

Factors Influencing Load Capacity

Several factors impact the load capacity of a drain system:

1. Material Selection: The type and quality of materials used in the construction of the drain system play a significant role in determining load capacity. Common materials include PVC, cast iron, concrete, and more. Each material has different load-bearing capabilities.

2. Design: The design of the drain system, including the size, slope, and configuration of pipes, is crucial for load capacity. A well-designed system can distribute loads effectively and minimize stress on individual components.

3. Installation: Proper installation is essential for ensuring that the drain system can withstand the intended loads. Incorrect installation can result in misaligned pipes, weak connections, or inadequate support.

4. Traffic and Use: The expected traffic and use of the area where the drain system is installed are significant factors. For instance, a parking lot drain system needs to withstand the weight of vehicles, while a residential system may primarily face hydraulic and static loads.

5. Environmental Conditions: Environmental factors, such as soil conditions, freezing temperatures, or corrosive substances, can impact the load capacity of drain systems. These conditions may lead to material deterioration or loss of structural integrity.

Design Considerations for High Load Capacity

Designing a drain system with a high load capacity involves several considerations:

1. Material Selection: Choose materials that are known for their strength and durability. PVC and cast iron are often preferred for their robust load-bearing capabilities.

2. Pipe Diameter and Thickness: Use pipes with adequate diameter and thickness to handle the expected loads. Larger pipes can accommodate more substantial hydraulic loads, while thicker walls can withstand static and dynamic loads.

3. Slope and Grading: Ensure that the drain system is designed with the appropriate slope and grading to facilitate efficient water flow and reduce the impact of hydraulic loads.

4. Reinforcement: In areas where the drain system may be exposed to high traffic loads, consider the use of reinforced concrete or reinforced pipe sections to enhance load capacity.

5. Protective Measures: Implement protective measures, such as using heavy-duty grates and covers for high-traffic areas to prevent impact loads from damaging the system.

Maintenance and Load Capacity

Proper maintenance is essential for preserving the load capacity of a drain system. Neglecting maintenance can lead to blockages, clogs, and damage that reduce the system’s ability to handle loads effectively. Maintenance tasks to consider include:

1. Regular Inspections: Frequent visual inspections can identify issues early, allowing for timely repairs.

2. Clearing Blockages: Removing debris, sediment, and foreign objects from drains, gutters, and downspouts is crucial to prevent blockages that can overload the system.

3. Professional Assessments: Schedule professional assessments by plumbers or drainage experts to identify and address potential issues before they become significant problems.

4. Snow and Ice Management: In cold climates, implement snow and ice management measures to prevent snow and ice from accumulating and blocking drain openings.

Realistic Expectations for Load Capacity

The load capacity of a drain system can vary significantly depending on the factors mentioned earlier. Some general expectations for different types of drain systems include:

1. PVC Drain Systems: PVC (polyvinyl chloride) drain systems are known for their durability and resistance to corrosion. Well-designed and installed PVC systems can handle both hydraulic and static loads effectively.

2. Cast Iron Drain Systems: Cast iron drain systems are robust and capable of withstanding high static loads, making them suitable for areas with significant weight-bearing requirements.

3. Concrete Drain Systems: Concrete drain systems can have high load capacity, but their susceptibility to corrosive substances may affect their durability in certain environments.

4. Clay Drain Systems: Clay drain systems are vulnerable to dynamic and impact loads, making them less suitable for areas with heavy traffic or other high-impact conditions.